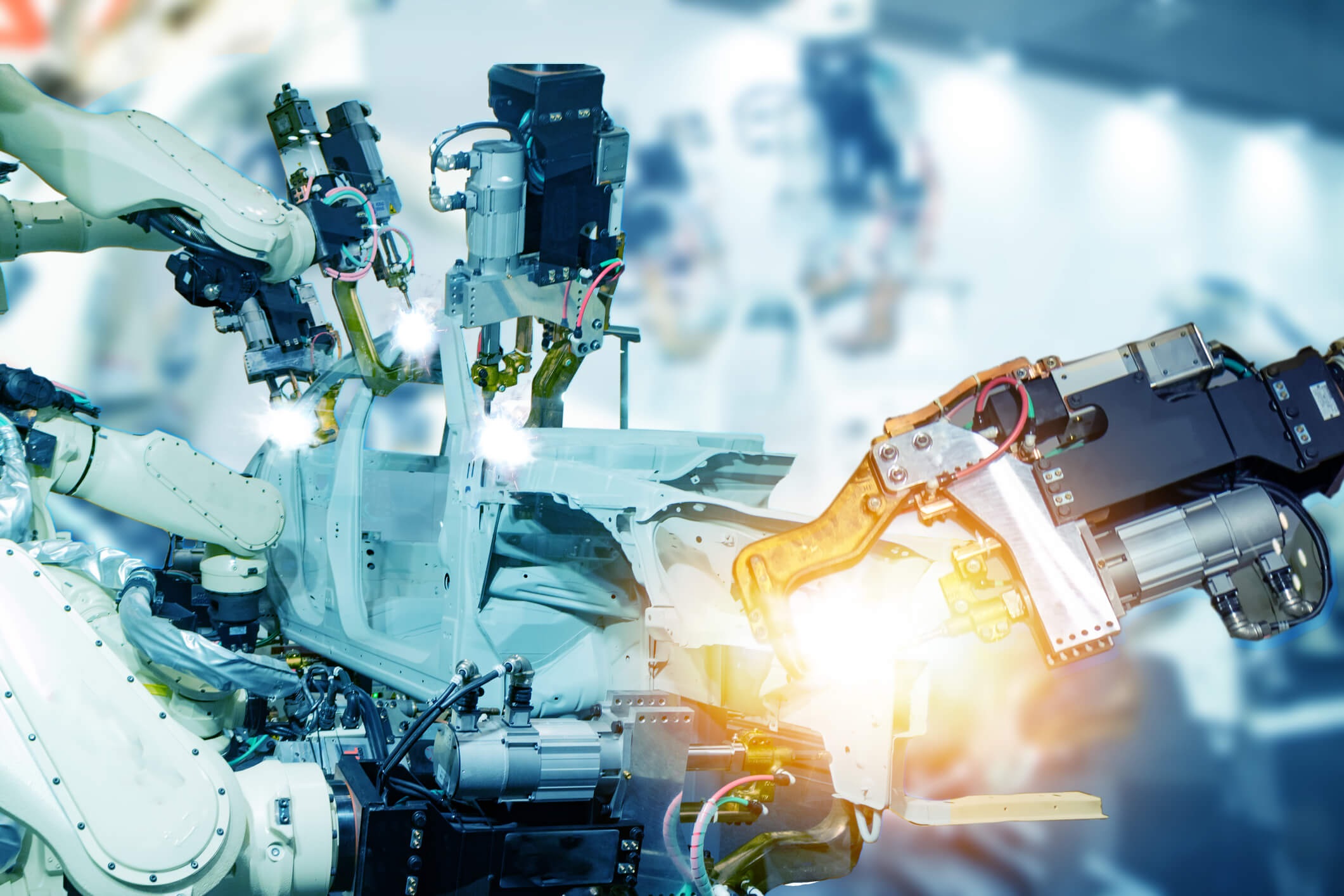

Robots were first introduced to the world of manufacturing in 1961 when the Unimate robot, the 4,000-pound arm, was incorporated in the General Motors assembly line. The first robot was amazingly versatile for its time. It completed tasks such as welding automobile parts together and pouring liquid metal diecasts with a lot of ease. The introduction of Unimate to the manufacturing world sparked a robotics revolution because they could complete dangerous and tedious tasks with a high degree of accuracy and speed that no human could attain.

Since then, the robotics industry has changed tremendously, increasing the ability of robots to take human characteristics such as trainability, dexterity, sensing, and memory. These advancements have increased their usefulness in the manufacturing industry. With each change, commercial robots take more tasks that could only be completed by humans.

Robots have revolutionized the manufacturing landscape because they can perform tasks repetitively with precision, and without getting tired. The advancements in technology have expanded the world of robots by creating developing robots that complete complex tasks with precision.

Collaborative Robots

Collaborative robots, also known as cobots, are responsible for the widespread use of robots in manufacturing industries. The new breed of robots can work together with humans in a collaborative environment. Humans can train these robots with physical demonstrations, and the cobot takes up the task. The use of artificial intelligence and machine learning has led to the creation of robots that can complete as many tasks as humans.

However, despite the developments in the robotics industry, they still need humans for programming and maintenance. The robotics industry continues to expand globally. In 2013, there were about 8 million robots in the manufacturing industries. Experts predict that the robotic industry will hit the $30 billion mark by 2025. Here’s how commercial robots have changed the manufacturing landscape.

Creation of New Job Opportunities

Since the widespread adoption of robots in manufacturing, many people have had the concern that robots will take away their jobs. Robots can indeed eliminate undesirable jobs that too repetitive or dangerous for humans. But what many don’t know is that robots help create new job opportunities such as engineering and programming. Modern robots haven’t gotten to the point where they can operate 100 percent autonomously. They will still need a human hand to complete some tasks. People who are currently working on the production floor will have enough time to learn new skills that they can use in the industry.

They Promote Efficiency in Manufacturing

The modern market is highly competitive, and companies can only thrive by streamlining their production lines to become more efficient and faster. One significant advantage of incorporating a commercial robot in a production line is that it can run for hours without compromising the quality of your products. They can work around the clock, which is more than what any human schedule can accomplish.

Since robots are highly precise, they can help eliminate mistakes that could potentially be made by human hand. Industrial robots can multitask without making mistakes, unlike humans, who can easily make costly mistakes while multitasking. Robots not only boosts productivity, but they can also have an impact on the local economies.

For instance, through increased productivity, companies will no longer need to relocate to countries with cheap and skilled labor. They can achieve all their manufacturing needs locally by incorporating robots in their processes.

Promoting the “Greening” of the Manufacturing Process

For the last few years, there’s been a growing interest in green manufacturing, with many companies incorporating manufacturing processes that promote energy and environmental conservation. Firstly, robots help improve manufacturing processes by minimizing the wastage of raw materials. It also leads to the production of less waste that enters the environment.

Most of the modern robots are highly energy-efficient, which makes them suitable for use on the production floor. Additionally, reducing the number of human workers on the production floor will lessen the need for heat, lighting, and air conditioning in the production facility.