In a soldering station for electronic components there are different tools that are essential to carry out a good job – a soldering iron with its support, cleaning paste, flux, pliers of different types, tweezers, and tools for clamp, pump, etc. A tool that is not taken into account and is essential in the welding activity, however small, is the fume extractor or Solder smoke extractor. However, it is a small tool. It is mainly composed of tin and lead, and its usual ratio is 60/40 respectively.

Why it is a must have?

This is because the vapors originating from the metals used in the soldering process are highly contaminating. And offer a wide range of health risks to the individual when inhaled. In this context, the smoke vacuum has the important function of removing these contaminants from the environment, which ensures safety and well-being for workers.

Lead is a harmful substance for living organisms. During welding activity the human body is exposed to this element and suffers poisoning. Both by inhalation and by absorption through the skin. During the welding process, the smoke generated in the process is inhaled in small doses. Therefore, a Solder smoke extractor becomes an essential tool when soldering electronic components.

Facts you need to consider

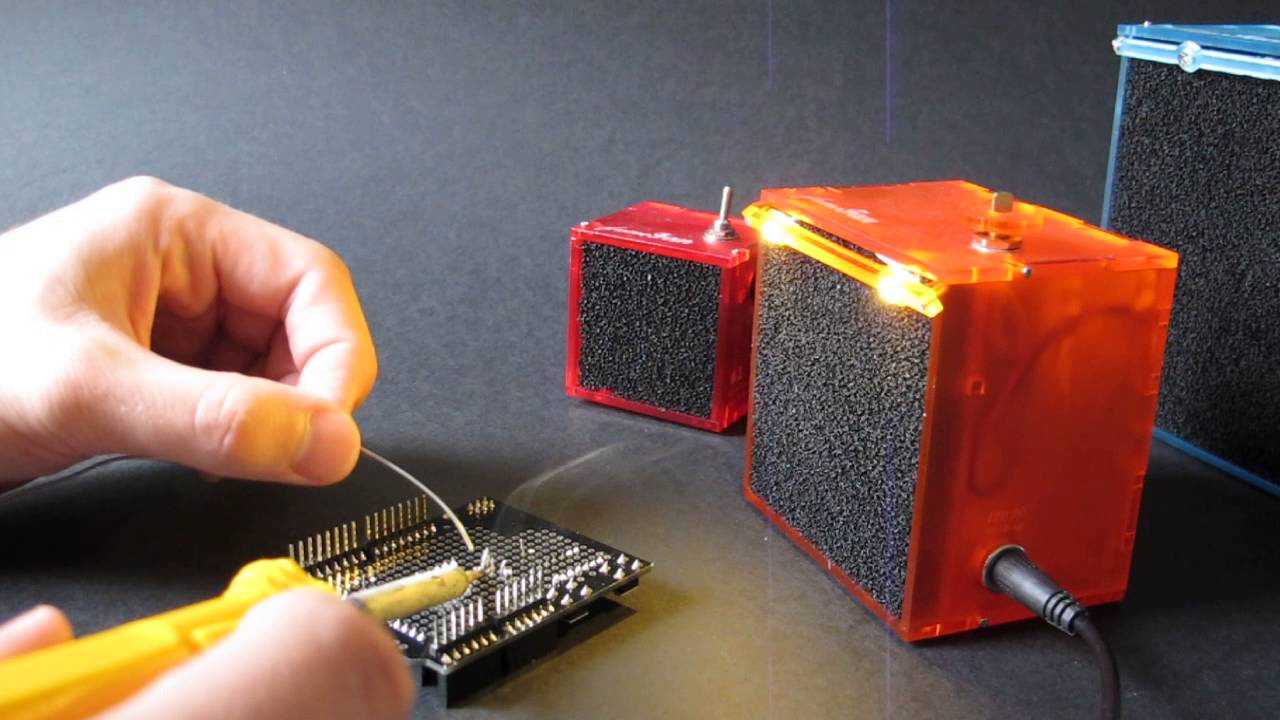

It should be noted that the smoke extractor must absorb the smoke in the fan area and dissipate it from the top. The optimal operating distance is between 5 and 15cm from the weld location. The fume extractor does not completely eliminate the smoke from the weld. But rather tries to deflect it from the face of the person who performs this activity. So it is convenient to do it in a well-ventilated place.

The use of protective glasses is recommended to avoid projections and splashes. Avoid touching your eyes while welding. It is advisable to wash your hands after soldering, to avoid absorbing lead through your skin. Wearing a mask is also suggested.

Conclusion: It has significant importance

In environments that adopt soldering, there has been a constant concern with the health and safety of workers. Especially with smoke, which is important causes of serious health problems. For this reason, many companies adopt the use of Solder smoke extractor in their processes.

In addition, the soldering smoke vacuum also provides a reduction in the maintenance costs of the company’s equipment. Since they also remove contaminants of various types, which when accumulated on surfaces and machines generate damage.